Hydraulic and Lubrication Oil Condition Monitoring.

Advanced laboratory techniques

Hydraulic and Lubrication Oil Condition Monitoring

Partnering with Wear Check, a leading condition monitoring specialist in South Africa, we perform detailed analysis of hydraulic and lubrication oil using advanced laboratory techniques.

Hydraulic and lubrication oil condition monitoring is a proactive maintenance practice that assesses the health of oils used in critical systems—hydraulic presses, gearboxes, turbines, compressors, and rotating machinery. The goal is simple: catch contamination, degradation, or wear early before they lead to catastrophic equipment failure.

Why Monitor Oil Condition?

Oil isn’t just a lubricant—it’s a vital machine component. Over time, exposure to heat, moisture, particles, and metal wear degrades its effectiveness. Monitoring allows you to detect:

Water contamination

Particle ingress (dust, dirt, metal shavings)

Oxidation and acidity (TAN/TBN shifts)

Viscosity breakdown

Additive depletion

Fuel or coolant dilution

Left unchecked, these conditions accelerate component wear, seal failure, overheating, and downtime.

Hydraulic and lubrication oil condition monitoring turns reactive maintenance into a proactive strategy. By watching the lifeblood of your machines, you catch problems before they escalate, reduce downtime, and extend the lifespan of your equipment. Whether you choose portable kits, online sensors, or full lab analysis—knowing your oil’s condition means knowing your equipment is safe.

Our Application

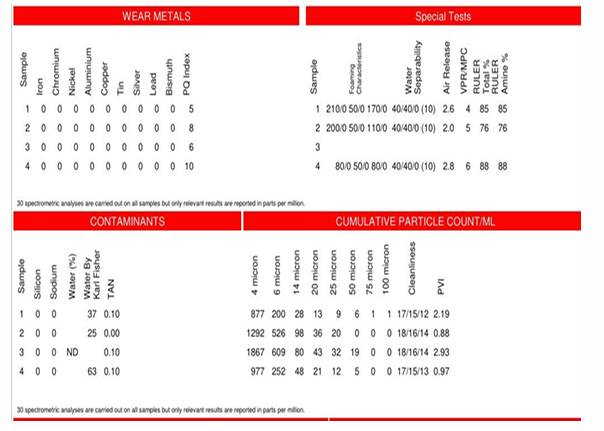

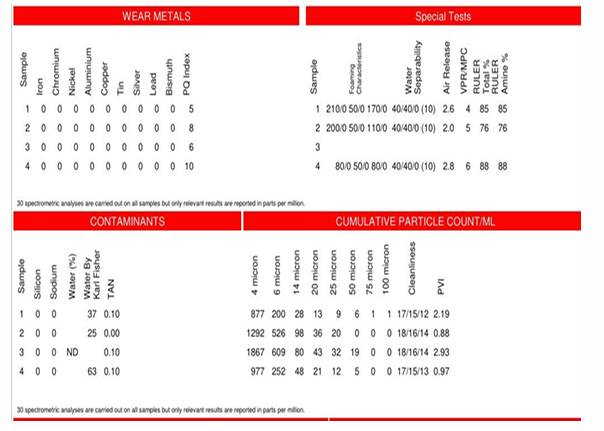

Wear Metal Analysis:

Identifies wear particles to detect component degradation.

Contaminant Analysis:

Detects water, dirt, or other contaminants that could damage equipment.

Specialized Testing:

Includes RPVOT, Varnish Potential (MPC) Testing, Particle Quantifier (PQ) analysis, and RULER testing to extend fluid life and prevent premature component wear.

Hydraulic and Lubrication Oil Condition Monitoring

Partnering with Wear Check, a leading condition monitoring specialist in South Africa, we perform detailed analysis of hydraulic and lubrication oil using advanced laboratory techniques.

Wear Metal Analysis:

Identifies wear particles to detect component degradation.

Contaminant Analysis:

Detects water, dirt, or other contaminants that could damage equipment.

Specialized Testing:

Includes RPVOT, Varnish Potential (MPC) Testing, Particle Quantifier (PQ) analysis, and RULER testing to extend fluid life and prevent premature component wear.